Business Need

The main part of any restaurant is, obviously, kitchen and food that is made there. But when a single restaurant grows into a famous country-wide chain, its kitchen is not about cooking anymore, it’s about the conveyor.

On this stage, the restaurant processes mainly fall under manufacturing rules so that each step would take the precise amount of time and each product would have standardized weight. A consumer would always be satisfied when getting a product of the same recognizable flavor.

And manufacturing rules require manufacturing approaches. Among them would be item monitoring on each preparation and storing stage, automatic triggering of alerts, and weight identifying.

Therefore we have developed remote food measurement software that allows to detect food type and identify products weight in real-time with 95% accuracy using the 3D video cameras and on-the-edge CV tech.

Solution

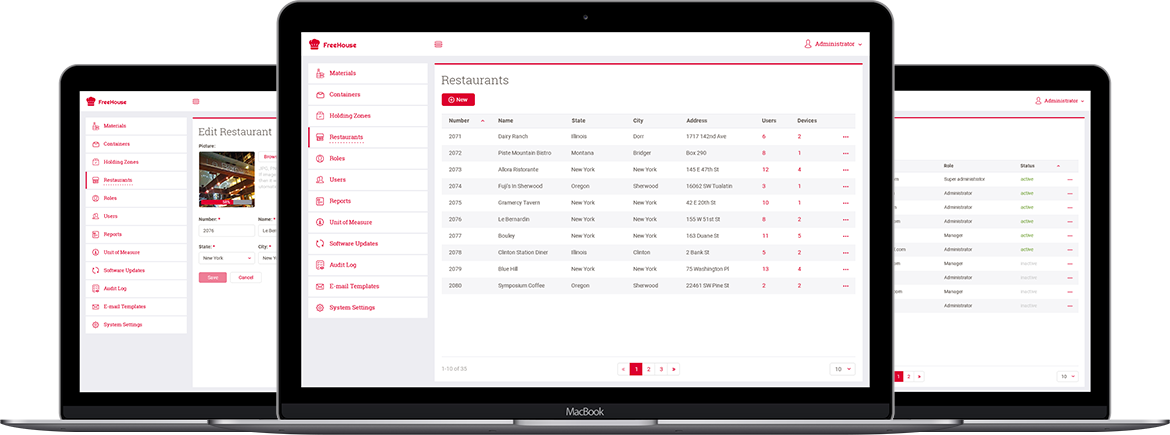

- Softarex Technologies, Inc. has designed the unique system to remotely measure the mass of homogeneous products with the help of video cameras operating in real time. It includes:

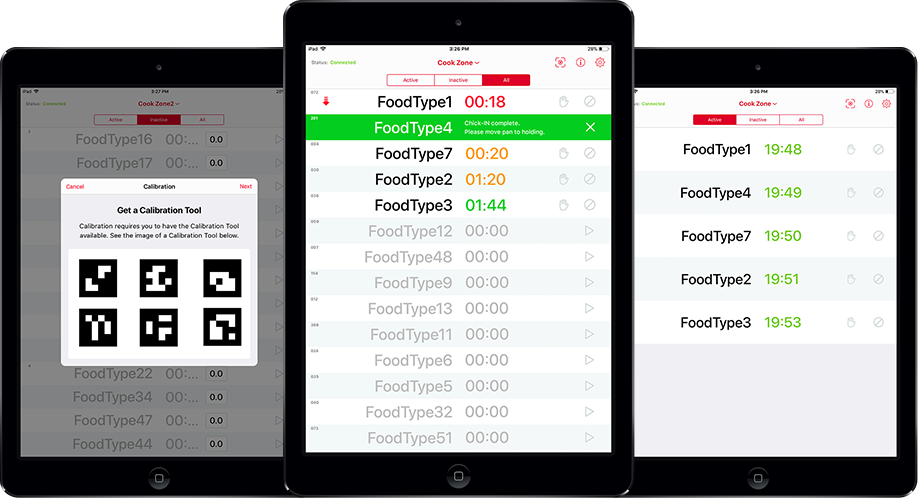

- An iPad application for restaurant operations;

- A real-time video stream system based on industrial PC;

- Cloud-based application for data collection and analysis.

The platform can easily cover the network of more than 2000 restaurants with seamless performance on the constantly high level due to its scalability.

Under NDA

- Product type and weight identification without its extraction from a workflow and use of extra time.

- The identification of food waste amount during the preparation process.

- Automatic time detection for each cooking stage and employees notification about delays.

- Product storage identification and employees notification about its shelf life ending.

- The system has revealed a surprising quantity of wasted and spoiled food due to poor timing of existing processes: more than 30% of food per week has never seen the guest. The value of such a discovery for the business can hardly be overestimated.

- The collected explicit metrics provide grounds for further prediction of food cooking for a particular restaurant.

- Monitoring of food preparation is improved with the system of timers and alerts. And with the system that keeps statistics for each container’s move, it became easier to analyze the flaws of the current workflow.

Technologies

- Java 8

- Redis

- PostgreSQL

- C++

- Angular 7

- Swift 4

Project Results

- As a result, Softarex has managed to bring an industrial approach to the kitchen and make it work as effectively as possible, providing the below set of features:

- Automatic food type detection — once container with food is placed under the 3D video cameras, the system automatically detects its content and identifies its type.

- Products weight identification — same 3D cameras detect the weight of identified product in real time with 95% accuracy.

- Containers tracking — as each container with food is identified by the cameras, it allows to monitor its movements throughout the kitchen.

- Time tracking — in order to help employees to make sure each container presents in the preparation zone the required time, the system is furnished with counters and alerts per each container, that is set automatically once a container is detected in a particular place, or manually by employees.

- Data collection and analysis — since the system keeps a record of each container movement and weight of the product throughout the whole process, it becomes really simple to collect data about wasted food and make predictions for food cooking for a particular restaurant.

To make this all work, every kitchen had to undergo a number of changes in order to create a proper environment and satisfy the system’s requirements. And our team has provided the full support of the overall deployment process, taken under control each and every restaurant.